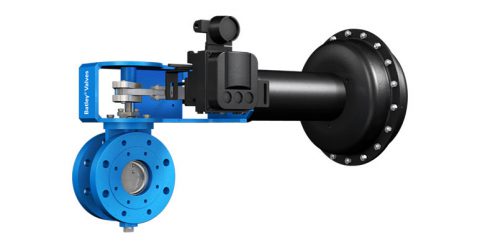

Tricentric® Triple Offset Butterfly Valves

General Details

Tricentric® Metal Seated Valves perform favourably when compared to conventional resilient seated and high performance butterfly valves over all services ranges. Tricentric® Triple Offset Valves incorporate 3-way eccentricity. The metal seat is capable of a very tight seal at temperatures up to 1,500°F.

Key features/benefits

- Triple offset metal seat design

- Long life seats

- Bi-directional tight sealing

- API 598 – zero leakage

- Excellent throttling characteristics

- Frictionless seating

- Robust shaft design to support full range of actuator torques

Applications

- Isolation & control

- High temperature

- Cryogenics

- Extraction steam isolation

- Oil & Gas isolation & control

- Nuclear containment

- Service water

- Condensate

- Circulating water

Processes

- Cryogenic (Power)

- Multipurpose flow control (Power)

- Multipurpose flow control (Industrial)

- Fluid flow control (Industrial)

- Fluid flow control (Power)

- Oil and gas production

- Refining and petrochemical (Industrial)

- Refining and petrochemical (Oil & Gas)

- Water and waste water

Spesification

|

Design standards |

ASME B16.34, API 609 5th Edition, ASME Sec III NC, ND (Nuclear), QME-1 |

|

Design ratings |

ASME 150 – 600 |

|

Size range/-dimensions |

3″ to 96″ (80 mm – 2,438 mm) |

|

Pressure class/-power |

ASME 150 – 600 |

|

Temperature range |

-400°F to 1,500°F |

|

Capacity |

N/A |

Materials

Cast carbon, alloy steel, stainless steel, or AL6XN

Upgrades/adaptations

- Hardened Containment Vent Systems