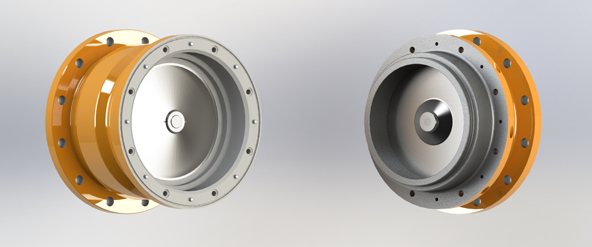

Flip-Flap Valve Marine Breakaway Coupling

Identified safe parting point

This Flip-Flap Marine Breakaway Coupling provides an identified safe parting point in marine hose transfer systems and automatically shuts off product flow in the event of an extreme tensile load being applied to the hose string following a tanker breakout, or an excessive pressure surge in the line during tanker loading.

Proven to protect

This design is suited to the rigors of the marine environment and reduces the risk of damage to assets, injury to personnel and harm to the environment.

Material composition

Offshore grade forgings are used for the main body components. The break assembly is made from high grade titanium alloy that is rated, tested and certified.

Extensive material testing combined with long term field experience ensures performance integrity and in-service reliability in all environmental conditions.

Materials can be varied to suit desired specifications.

Torsion spring backup system

The torsion springs are bias and is a backup system. The springs are therefore not depended upon to close the valve. The springs will effect closure where there is no product flow when breakout occurs.

Breakstud

The final breakstud rating is determined following basic calibration and proof tensile testing on sample breakstuds. These samples are machined from the same titanium material in its final treated condition as used in the final product.

These breakstuds are not shearbolts and therefore act in controllable tension.

Calibration

The unit can be pre-set to suit the limitations of the product transfer system in respect of linear overload and pressure surge.

Double closure

Double closure design provides valve closure on both the upstream and downstream sides of the separation point.

Instant closure

Closure delivers instant shut-off. This is suitable for operations with lower loading rates or short piping systems where damage to asset due to instant closure is unlikely.

Controlled closure

Variable valve closure speeds provide anti-line shock shutdown to protect up-line assets such as pumps, meters, hoses and gaskets for higher loading rate systems.

Standard unit:

The Standard Unit will activate in two circumstances.

Linear overload:

The Standard Unit will part on linear overload. This may occur due to a tanker moving off station due to a manoeuvring fault, an unexpected wave, wind or general inclement weather conditions.

In cases of tanker breakouts or extreme pressure surge incidents where no MBC is installed, the consequences can be horrendous, with ruptured hoses and major oil spills. However, with an MBC installed system damage will be avoided and pollution will be prevented.

Flow pressure surge:

The Standard unit will activate where an extreme internal pressure surge occurs: caused by an unusual event such as an inadvertent sudden valve closure downstream of the breakaway coupling.

Stabilised unit:

The Stabilised unit will activate in one circumstance.

Linear overload:

The Stabilised Unit will activate on linear overload as with the Standard Unit.

Flow pressure surge:

The Stabilised Unit will not activate due to a pressure surge but is instead designed to possess the same integrity as the rest of the transfer system.