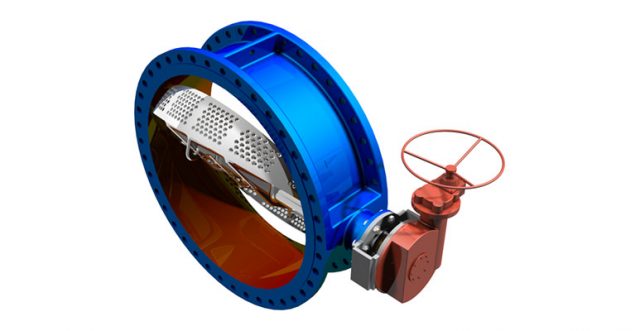

Batley Valve® BV 30000 – Varidiff Vane

Varidiff trim incorporates two hemi-spherical control elements on opposite sides of the vane to reduce the pressure recovery particularly at low openings: a value of 0.9 is achieved compared with 0.7 for a standard vane. Further efficacy is achieved by adding an integral baffle. For higher openings the pressure drop is broken down across the vane and the baffle plate which results in a reduction in pressure recovery. The flow characteristic is equal percentage with a turn down in excess of 100:1. Due to the low dynamic torque a stable mode of operation is maintained 5 and 80 degrees opening.

Key features/benefits

- Reduces problems in potentially cavitating services

- Extensive range of body & trim options

Applications

- Back pressure control on overboard dump lines in the offshore industry

- Other applications include firewater ring system control valve, brine blowdown control, jetty loading valves, sea-water drain and re-circulation, cooling water circulation, and distulate to culvert valves

- In addition to the above liquid service applications it has also found use on steam vent headers, and gas pipelines, for low noise requirements

Processes

- Low noise (Power)

- Low noise (Industrial)

- Oil and gas production

| Design standards |

API 609, BS 5155, MSS SP68, API 598, BS 6755, FCI 70.2, ANSI B16.34, ISO 5752, DIN 3202 |

| Design ratings |

ASME 150 |

| Size range/-dimensions |

100mm to 1200mm (4″ to 48″) |

| Pressure class/-power rating | N/A |

| Temperature range |

30°C up to 220°C (86°F to 428°F) |

| Capacity | Up to 26000 |

Materials

All castable materials: Carbon Steel, Stainless Steel, Duplex, Super Duplex, Hastalloy, Inconel, Monel, Titanium, etc.

Trim Materials: Austenitic SS,17-4 PH, Duplex/Super Duplex SS, Various hard surfaces to seat & seal ring available (stellite, tungsten carbide).

Upgrades/adaptations

-

Material Reinforced Aluminium/Bronze