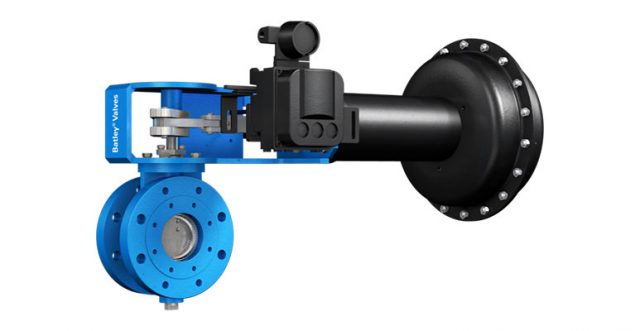

Batley Valve® BV 26000 – Metalseal

The Batley Valve® Metalseal Butterfly Valve is used in applications where high operating temperatures or abrasive service preclude the use of elastomer or polymeric seals, but a superior shut-off is still required. This design is an inherently fire safe design and has a shut-off to ANSI/FC I-70-2 class IV. Double offset design and geometry of the valve and seal combine to ensure a uniform 360° seal contact in the closed position. The double eccentric action of the disk minimises wear and seating torque. Hard surface deposits such as hard Chrome plating, Stellite & Tungsten Carbide are available.

Key features/benefits

- The Metalseal design suitable for high temperatures and abrasive service where a PTFE seal is not usable.

- Valve is suitable for higher pressure and temperature than PTFE allows.

- The vane’s streamlined design improves the flow line and reduces the head loss.

- ANSI Class IV leakage as standard.

- Special valves can be manufactured with Bodies drilled to suit flanges up to ANSI Class 2500lb.

- The valve can be supplied with Wafer, Lugged and Double Flanged bodies and incorporating full and reduced bore sizes to suit the application.

- Seat design enables stable tight shut off performance both in direct and reverse flow conditions.

- Alternative seal retainer available to suit spiral wound gaskets. Sizes up to 1200mm on request. Butt weld body designs available on request.

Applications

- Multipurpose Low, Medium and High pressure with Metal to Metal seal for high and very high temperature

- Slurry services

Processes

- Slurry transportation

- Multipurpose flow control (Power)

- Multipurpose flow control (Industrial)

| Design standards |

API 609, BS 5155, MSS SP68, API 598, BS 6755, FCI 70.2, ANSI B16.34, ISO 5752, DIN 3202 |

| Design ratings |

ASME 150# to 2500# |

| Size range/-dimensions |

150mm to 1000mm (6″ to 80″) |

| Pressure class/-power rating | N/A |

| Temperature range |

-196°C to 900°C (-320°F to 1652°F |

| Capacity | N/A |

Materials

All castable materials: Carbon Steel, Stainless Steel, Duplex, Super Duplex, Hastalloy, Inconel, Monel, Titanium, etc.

Trim Materials: Austenitic SS, 17-4 PH, Duplex/Super Duplex SS, Various hard surfaces to seat & seal ring available (stellite, tungsten carbide).

Upgrades/adaptations

- Upgrade to leakage ANSI Class V, MSS SP61 & API 5 available